TECHNOLOGY

PATENT ABSTRACTS OF JAPAN

H31-6474200 Double clutch device |

H30-6344733 Brake device |

H29-6222790 Brake device |

H29-6222789 Brake device |

|

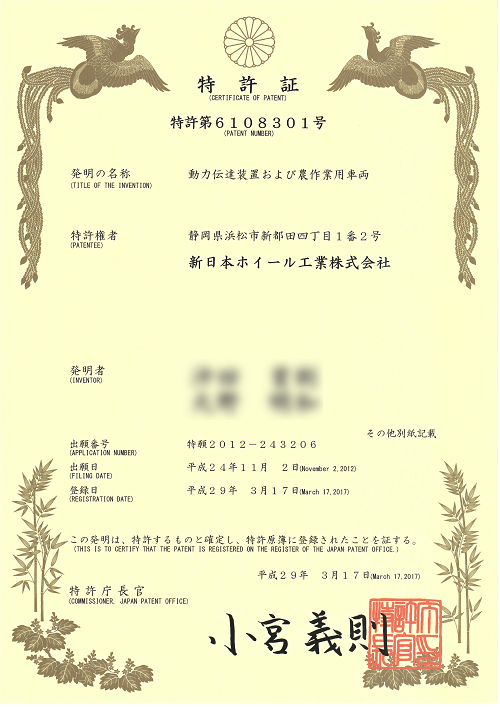

H29-6108301 Power transmission equipment and agricultural work vehicles  |

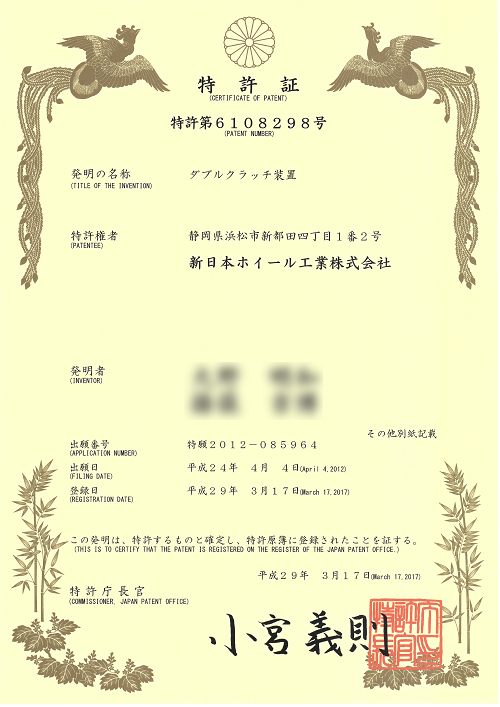

H29-6108298 Double clutch device |

2001-248670 : BRAKE DEVICE FOR BUGGY VEHICLE

H11-270579 : MULTI-DISK TYPE FRICTION CLUTCH

H11-029013 : BRAKING DEVICE FOR BUGGY

H10-122258 : TRAILING PREVENTION DEVICE OF WET TYPE MULTI-PLATE CLUTCH

H08-164867 : LUBRICATING DEVICE FOR MULTIPLE DISC CLUTCH

H07-233827 : STEERING BRAKING CLUTCH FOR SMALL TYPE TRAVELING AGRICULTURAL MACHINE

2003-240016 : OUTER RING STRUCTURE FOR HYDRAULIC CLUTCH

2001-018672 : PTO SHAFT DEVICE FOR TRACTOR

2000-289644 : STEERING DRIVE DEVICE FOR TRAVEL VEHICLE

2000-052943 : BRAKING DEVICE FOR VEHICLE

H11-291877 : BRAKE DEVICE FOR SHAFT-DRIVEN VEHICLE

H11-198672 : BRAKING DEVICE FOR PTO SHAFT IN TRAVELING AGRICULTURAL MACHINERY

H11-170989 : BRAKING DEVICE FOR BUGGY

H10-331864 : CREEP PREVENTION DEVICE FOR MULTIPLE DISC CLUTCH

H10-311356 : BRAKE CLUTCH FOR STEERING

H10-264672 : OPERATION DEVICE FOR FRICTION CLUTCH

H09-267601 : CAST WHEEL AND FINISHING THEREOF

H09-242788 : PARKING BRAKE OF MOVING AGRICULTURAL MACHINE OR THE LIKE

H08-258674 : PARKING BRAKE DEVICE OF SELF-MOBILE WORKING MACHINE

H08-257068 : CENTER-OF-GRAVITY MOVING DEVICE FOR WHEELCHAIR

H08-257067 : CENTER-OF-GRAVITY MOVING TYPE WHEELCHAIR

H08-207822 : STEERING BRAKE DEVICE FOR SELF-TRAVELING WORK MACHINE

H07-000029 : BRAKING CLUTCH FOR FARMING MACHINE OR THE LIKE

H06-239264 : OPERATION DEVICE FOR CLUTCH BRAKE